WHAT IS COFFEE

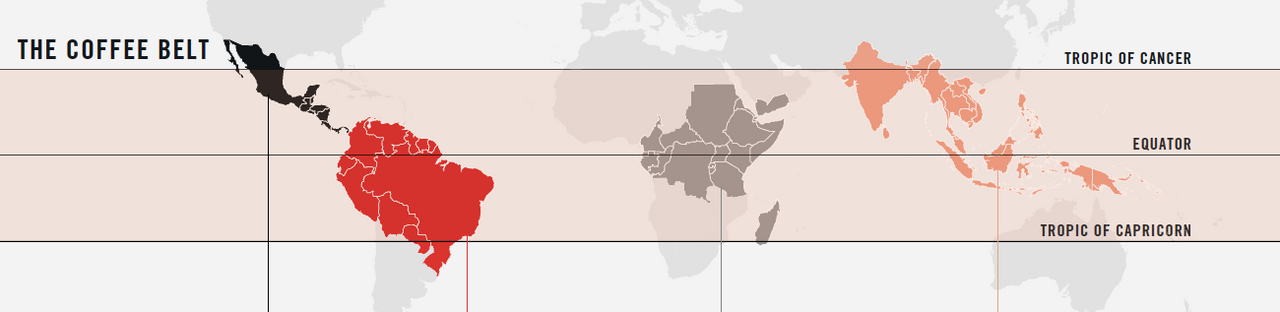

Coffee is a dark, aromatic drink prepared with roasted coffee beans. Harvested from a species of Coffea plant (of which there are approximately 80 species known throughout the world), coffee beans require a well-defined climate and altitude characterised by relatively high temperatures and alternating sunshine and rain. The Coffea plant is usually grown in tropical zones – hence why coffee is inextricably linked to the health of the tropical rainforest.

COFFEE FROM AROUND THE WORLD

Coffee plants grow in several geographical areas, and for this reason the oils and fats that determine the bean aroma vary according to temperature, the degree of humidity and the earth the plant grows in.

CARIBBEAN AND CENTRAL AMERICA

Coffea Aribica Acidulous, light-bodied and highly aromatic coffee bean, and tends to be the predominant type cultivated by the washed method.

Countries: Porto Rico, Cuba, Haiti, Jamaica, Santo Domingo, Costa Rica, Guatemala, Honduras, Mexico, Panama, Salvador, Nicaragua.

SOUTH AMERICA

Mainly washed and natural Arabica: Acidulous, light-bodied and highly aromatic

Countries: Colombia, Venezuela, Peru, Bolivia.

Natural Arabica: Mild, medium-bodied and balanced.

Countries: Brazil

AFRICA

Washed Arabica: Acidulous, light-bodied and highly aromatic.

Countries: Ethiopia, Kenya, Tanzania, Burundi and Zimbabwe.

Natural Arabica: Mild, medium-bodied and balanced.

Countries: Ethiopia.

Natural Robusta: Strong, full-bodied and woody.

Countries: Uganda, Cameroon, Congo, Togo and the Ivory Coast.

ASIA

Washed Robusta beans: Strong, are full-bodied and chocolaty.

Countries: Java, India, Indonesia, N. Guinea.

Washed Robusta beans?: Strong, full-bodied and woody.

Countries: India, Indonesia and Vietnam.

Natural Arabica: Neutral to mild, medium-bodied and balanced.

Countries: India.

HARVESTING METHODS

There are two ways coffee beans are usually harvested, by picking or stripping. Picking is a fully manual procedure by which only ripe fruits are picked by hand. The method is usually slower and more expensive but results in a higher quality fruit yield and a more even harvest.

Stripping is a procedure that can be performed by hand or machine and involves stripping the plant of its fruit and leaves. This method is usually faster and more cost-effective, however is more likely to cause damage to the plants and result in a more uneven harvest.

PRODUCTION METHODS

After harvesting, the coffee bean is separated from the pulp and leaves using either a washed bean method or unwashed bean method.

The washed bean method is a water-based treatment after picking, whereby the beans are washed to remove any mucilage, before being dried. This method tends to be more time-consuming, complex and costly however ensures a high-quality, aromatic and clean-tasting coffee.

The unwashed method involves drying the whole coffee cherry after the fruit is stripped. This method tends to be quicker, more economical and ecological but results in a heavier tasting coffee, as the drying beans absorb the sugars from the surrounding fruit.

BEAN ROASTERS

There are two types of coffee roasting machines: Rotating drum and fluid bed.

The rotating drum has an operating principle based on conduction convection and is roasted by direct contact with the drum walls and heated by flame with a hot airflow. The roasting time varies between 8 and 15 minutes.

The fluid bed has an operating principle based on convection, hot airflow (allowing a more even roast), temperature adjustment and accurate timing. The roasting time varies between 8 and 15 minutes.

ROASTING METHODS

The heat used in roasting causes the coffee beans to undergo a veritable transformation. A reduction in moisture from 8%-12% to 1%-5%, a 15%-20% reduction in weight, and a 30% - 60% increase in volume. The beans also become darker in appearance and their aroma begins to develop.

Following roasting, the coffee beans are then rapidly cooled to ensure the internal condensation of aromatic substances.

There are two cooling methods used: Air cooling and water cooling. Air cooling uses cold airflow and rapid cooling. This method tends to cause a slight loss of aroma and prevents the emission of carbon dioxide, causing subsequent difficulties during packaging.

Water cooling uses a fine spray in precise quantities. This causes a slight reduction of aroma and increases coffee bean weight, moisture, and volume if incorrectly dosed.

PACKING AND STORING ROASTED BEANS

The storage conditions of roasted coffee must be hygienic and prevent contamination of the product by volatile substances such as oxygen (which can cause oxidisation) and moisture (which can increase the growth of mould).

Highly professional companies with renowned traditions such as Saquella, do not package coffee immediately after roasting, preferring to let the roasted beans settle and mature in silos. This process ensures the development of fats and oils - which determine the aromatic base and full flavour of coffee - as well as the aroma and consistency typical of real Italian espresso.

SEARCH OUR PRODUCT RANGE

UCC Direct brings you a selection of our branded coffee, side products and entry-level boxed commercial coffee machines for quick and easy daily outlet maintenance. Click below to grow your coffee offer! Not sure of what to order? Our customer service team will be delighted to help with any further questions. Happy shopping!